In quick

- Wandercraft, the French business understood for its medical exoskeletons, has actually gotten in the field of humanoid robotics.

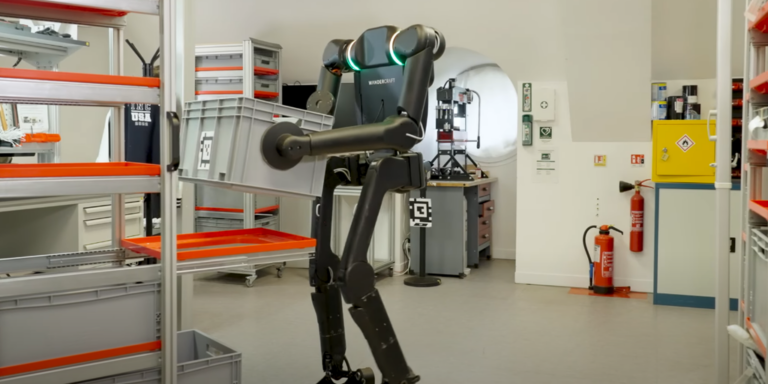

- Integrated in simply 40 days utilizing the very same core innovation as its exosuits, Wandercraft stated Calvin 40 is currently being evaluated in commercial environments.

- The robotic leaves out humanlike functions consisting of a head and hands, and concentrates on useful, harmful jobs that are tough or hazardous for human employees.

After catching worldwide attention at the 2024 Olympics, where its exoskeleton assisted a paraplegic male walk, Paris-based Wandercraft is now moving its focus from wearable robotics to completely self-governing humanoid robotics.

Wandercraft’s brand-new humanoid robotic, Calvin 40– so called due to the fact that it was supposedly integrated in simply 40 days– is currently being evaluated on factory floorings. As Wandercraft CEO Matthieu Masselin discussed, the fast building and construction of Calvin 40 was allowed by repurposing innovation from the business’s exoskeletons.

” You see all these humanoid robotics all over– Tesla, Figure AI, business in China– and for us, it’s the very same innovation we have actually been establishing for the last ten years,” Masselin informed Decrypt in an interview. “It felt so natural for us.”

Masselin stated the business was likewise able to produce Calvin 40 so rapidly in part due to the fact that it left out the head and hand functions usually discovered in humanoid robotics, such as Tesla’s Optimus or Figure AI’s Figure 02.

” We’re not concentrated on including a head, due to the fact that it does not assist with navigation, the very same chooses hands, hands are extremely vulnerable,” he stated. “Our company believe we have a humanoid robotic that can bring the heaviest payload.”

Rather of hands, Calvin 40 utilizes cushioned, arm-like grippers with flat circular panels to get boxes and cages.

Masselin stated the head and hands were likewise excluded to prevent the remarkable valley impact, a pain individuals feel when connecting with robotics that appear practically– however not rather– human.

” Meaningful control matters in homes or specific scenarios, however in our case, an easier style is simply as reliable,” he stated.

Humanoid robotics have actually risen in appeal in the last few years. According to a February 2024 report by Goldman Sachs, the worldwide market for humanoid robotics is anticipated to reach $38 billion by 2035, driven by advances in AI and automation.

While some humanoid robotic designers have actually concentrated on social interaction or individual help, Masselin stated Wandercraft’s style options stress physical labor in areas constructed for individuals.

” A lot of environments are constructed for the human kind that it’s tough to deal with all requirements without simulating it,” he stated, including that the business is dealing with partners to release Calvin 40 in “harmful” or hard-to-staff jobs.

” Among the greatest differentiators of our innovation is that it was initially developed– and is still utilized– to establish an exoskeleton, which is a robotic that brings a human depending on 220 pounds,” Masselin stated. “That indicates the innovation needs to deal with that sort of payload.

According to Wandercraft, Calvin 40 can bring payloads of as much as 40 kgs, or about 88 pounds– almost two times as much as equivalent robotics like Tesla’s Optimus or Figure AI’s Figure 02, which are ranked to bring around 45 pounds.

” No other humanoid robotics can bring that much, by a broad margin– mostly due to the fact that they focus a lot on hands,” Masselin stated.

According to Wandercraft, the Calvin 40 is presently being evaluated by French international vehicle producer Renault Group, however he decreased to supply a rate for the robotics.

By recycling core innovation from its exoskeletons, Masselin thinks Wandercraft can avoid the speculative stage and concentrate on releasing robotics in commercial environments.

” We deal with our partners to comprehend their requirements– where they have jobs that are too tough, too hazardous, or difficult to employ for,” he stated. “The concern ends up being: Can we provide a much safer option for harmful tasks so that employees can concentrate on quality and workmanship? That’s the method.”

Modified by Andrew Hayward

Normally Smart Newsletter

A weekly AI journey told by Gen, a generative AI design.